The Role of Custom Slitting in the Global Supply Chain

Introduction

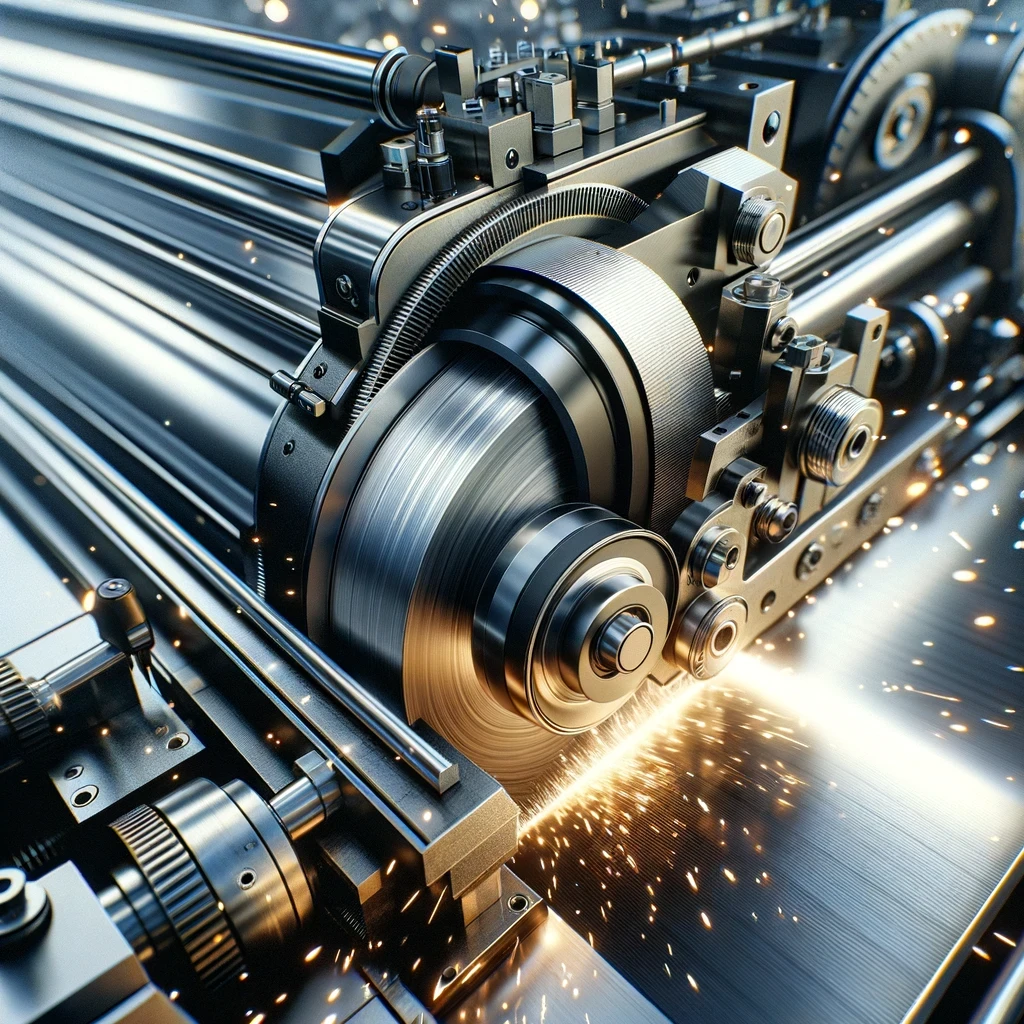

Custom slitting plays a pivotal role in the global supply chain, offering tailored solutions in packaging, printing, and manufacturing industries. This article delves into the essence of custom slitting, its benefits, applications, and trends shaping its future.

What is Custom Slitting?

Custom slitting involves resizing materials like plastic, paper, metal, and textiles to meet specific customer requirements. This section could use a table to compare custom slitting with traditional methods, highlighting its precision and customization capabilities.

| Feature | Custom Slitting | Traditional Methods |

|---|---|---|

| Customization | High | Low |

| Precision | Exact specifications met | General specifications |

| Efficiency | Reduced waste, tailored cuts | Potential for overproduction |

Advantages of Custom Slitting

Custom slitting offers numerous benefits, which can be outlined in bullet points for clarity:

- Increased Efficiency: On-demand cutting reduces inventory and waste.

- Improved Accuracy: Ensures products meet exact size requirements.

- Greater Flexibility: Easily adapts to changing market needs.

- Enhanced Branding: Supports unique packaging designs.

- Cost Savings: Minimizes scrap and unnecessary inventory.

Disadvantages of Custom Slitting

Despite its benefits, custom slitting has drawbacks:

- Increased Costs: Specialized cuts may incur higher expenses.

- Limited Availability: Not all materials are suitable for custom slitting.

- Reduced Efficiency: Additional production steps could slow down processes.

- Quality Concerns: Potential for defects if not properly managed.

Our team of seasoned converting experts will ensure that you are not impacted by these common drawbacks.

Applications of Custom Slitting

Custom slitting’s versatility spans various industries, illustrated through bullet points:

- Packaging: Custom shapes and sizes for protective films.

- Printing: Tailored paper or plastic films for unique projects.

- Textiles: Specific fabric dimensions for clothing and upholstery.

- Plastics and Metals: Specialty profiles and precise sheet cuts.

Custom Slitting in the Global Supply Chain

A table could effectively show how custom slitting enhances supply chain efficiency:

| Aspect | Impact of Custom Slitting |

|---|---|

| Material Optimization | Tailors production, reducing waste |

| Market Responsiveness | Quick adaptation to consumer preferences |

| Logistics Simplification | Fewer SKUs, streamlined inventory management |

Best Practices for Implementing Custom Slitting

Implementing custom slitting within manufacturing processes can significantly enhance production efficiency, reduce waste, and meet precise customer specifications. However, to achieve these benefits, companies should adhere to several best practices:

1. Understanding Material Properties

- Analysis: Begin with a thorough analysis of the materials to be slit, understanding their properties such as thickness, tensile strength, and potential for deformation.

- Compatibility: Ensure the slitting machinery and techniques used are compatible with the material properties to avoid damage and ensure quality cuts.

2. Investing in Advanced Equipment

- Precision Machinery: Invest in high-quality slitting machines that offer precision cutting capabilities and can be adjusted for various materials and sizes.

- Maintenance: Regular maintenance of equipment is crucial to prevent downtime and maintain cutting accuracy.

3. Training and Expertise

- Skilled Operators: Ensure operators are well-trained in using slitting machinery and are knowledgeable about different materials and cutting techniques.

- Continuous Learning: Encourage ongoing training and knowledge sharing to stay updated with the latest slitting technologies and methodologies.

4. Quality Control Measures

- Standards: Implement strict quality control standards to monitor the slitting process and the final product dimensions.

- Feedback Loop: Establish a feedback loop with the quality control team to continuously improve the slitting process based on real-world outcomes.

5. Efficiency and Waste Reduction

- Process Optimization: Continuously evaluate and optimize the slitting process to maximize efficiency and minimize waste.

- Recycling Initiatives: Implement recycling initiatives for scrap material to promote sustainability and reduce costs.

6. Customization and Flexibility

- Client Collaboration: Work closely with clients to understand their specific needs and customize the slitting process accordingly.

- Adaptability: Stay adaptable and be willing to modify processes to meet changing market demands or client requirements.

7. Safety Protocols

- Safety Measures: Enforce strict safety protocols to protect operators from the high-speed cutting and machinery used in the slitting process.

- Regular Training: Regular safety training and equipment checks ensure a safe working environment.

Adopting best practices for custom slitting is essential for businesses aiming to enhance their production capabilities and meet the specific needs of their customers. By focusing on material properties, investing in advanced equipment, ensuring skilled operation, and implementing quality control measures, companies can achieve greater efficiency, flexibility, and safety in their slitting operations. As the market for customized materials continues to grow, the ability to adapt and optimize slitting processes will be a key factor in maintaining competitiveness and satisfying customer demands.

Trends in Custom Slitting

Emerging trends show the evolving landscape of custom slitting:

- Automation: Enhancing precision and reducing errors.

- Sustainability: Increasing use of recyclable materials.

- Industry Expansion: Broader application across sectors.

- E-commerce: Demand for unique packaging solutions.

- Collaboration: Partnerships between suppliers and customers to innovate.

Conclusion

Custom slitting offers significant advantages for businesses seeking efficiency and customization. However, considerations around cost, technical requirements, and environmental impact are crucial. The right strategy can leverage custom slitting to improve supply chain dynamics and meet specific market needs.

FAQ

What is Custom Slitting?

- Cutting materials into specific sizes or shapes per customer requirements.

How Does Custom Slitting Enhance Efficiency?

- By reducing inventory and waste through on-demand production.

What Materials Can Be Custom Slit?

- Plastics, paper, metal, and textiles, among others.

Advantages Over Traditional Methods?

- Custom slitting provides precision, flexibility, and cost efficiency.

Can It Be Applied in Any Industry?

- Yes, particularly in packaging, printing, textiles, and more.

What Are the Disadvantages?

- Potential for increased costs, limited material options, and efficiency challenges.

Role in the Global Supply Chain?

- Optimizes production and responds swiftly to market demands.

Environmental Considerations?

- Focus on sustainable practices and recyclable materials.

Impact of Technology?

- Automation boosts efficiency and accuracy.

Considerations Before Implementation?

- Assess costs, expertise needed, and potential environmental and quality impacts.